GREEN IRON AND GREEN STEEL

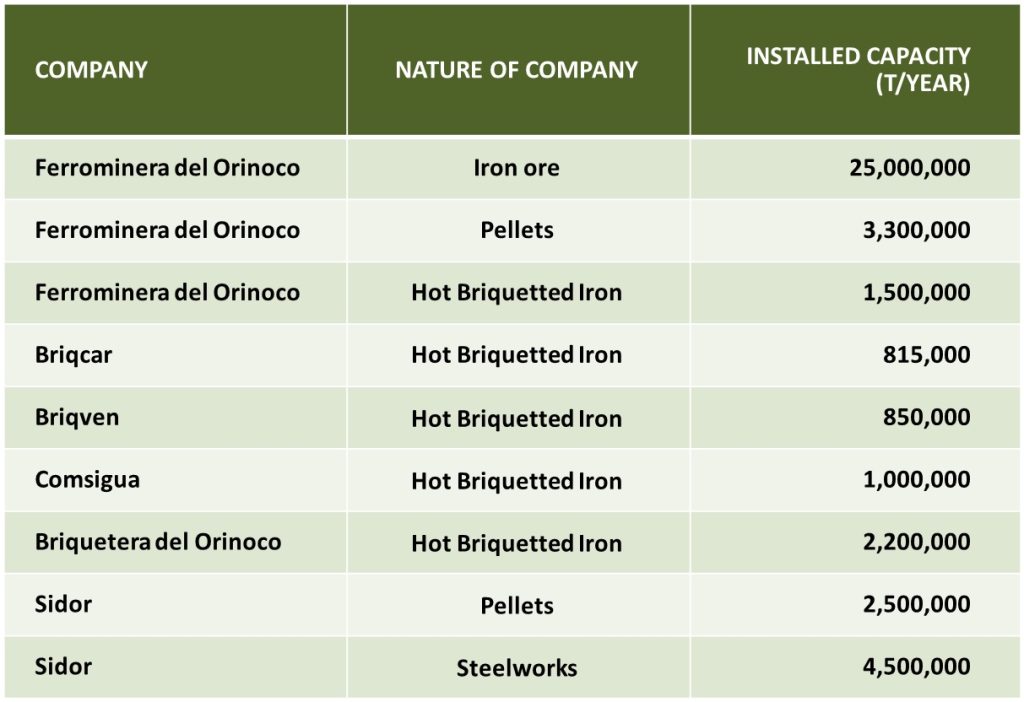

Venezuela already has an important iron and steel industrial park, which covers the exploitation of

ore, pellets, briquettes, liquid steel, rolled products, wire rod, billets, rods, etc

GREEN IRON

The Guayana Region is a land of enormous deposits of different metallic and non-metallic minerals. Among the most abundant mineral resources are iron, bauxite, gold, manganese, titanium, granite, coltan, and diamond.

In the case of iron ore, the main company is CVG Ferrominera Orinoco C.A., which has a current installed capacity of 25 MM t / year. This is generated in:

- Mines (Extraction and Processing of ore): 25 MM t / year

- Pellets Plant (Pre-reduced): 3.3 MM t / year

- Hot Briquetted Iron (Steelworks): 1.5 MM t / year

Currently under construction is a Second Pellets Line of 2.5 MM t / year and a Quartzite Concentration Plant to process 12 MM t / year and produce 8 MM t / year.

With proven reserves of 4,200 million tons (MM t), the company carries out its own transport of ore between the mines and the production centers, and at the same time between them and the docks through a system of railways and ships.

Additionally, it has an open water Transfer Station at the mouth of the Orinoco River with a storage capacity of 180,000 t, which allows it to carry out movements of more than 6 MM t / year.

GREEN STEEL

In the Guayana Region, the steel industry is vertically integrated with the

extraction and processing of iron ore in several existing companies.

SIDOR is the largest of these companies, and its processes begin with the manufacture of pellets and culminate with the delivery of Long (Bars and Wire Rod) and Flat (Hot Rolled, Cold Rolled and Coated) final products.

The other companies are dedicated to the production of pellets and hot briquetted iron, which allows for a significant availability of raw materials for use in industrial applications that require reliable supplies of steel.

LOW CARBON FOOTPRINT STEEL

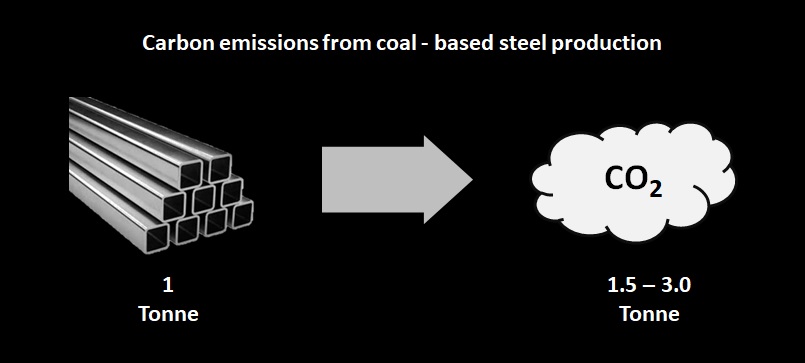

Steel production accounts for 8% of total global CO2 emissions; therefore, emissions from steel production must decrease for industry to achieve net-zero emissions by 2050 and for countries to deliver on the commitments made in the Paris Agreement.

Today, most crude steel is produced by reducing iron or using coal. The industry’s blast furnaces are highly energy intensive and rely on fossil carbon as a fuel and reduction agent.

For each tonne of steel produced in the conventional blast furnace-basic oxygen furnace route, between 1.5 and 3 tonnes of fossil carbon are released into the atmosphere.

But, as Venezuela has extensive natural gas reserves, iron and steel production, as well as downstream processes, use natural gas. Moreover, the electricity used is generated from renewable sources, predominantly hydroelectric generation, therefore in Venezuela the Iron and Steel industry already has a Low Carbon Footprint.

Additionally, since Venezuela has sufficient hydroelectric energy available, as well as great wind and solar potential, Green Hydrogen can be produced at very competitive costs, which, when used instead of natural gas, would further reduce the current Low Carbon Footprint in its Iron and Steel Industry.